Digital Twinning

A digital twin is a real-time digital replica of a physical asset, system, or environment, used to monitor performance, run simulations, and support decision-making throughout its lifecycle. Aligned with ISO 30173:2023, it ensures standardised data management and interoperability across platforms. Unlike traditional simulations, a digital twin can run multiple scenarios simultaneously, providing insights at scale. By combining 3D graphics, real-time data, and virtual or augmented reality, digital twins offer an accurate, always-updated model, ideal for testing, optimisation, and integration without affecting real-world operations.

Methodology

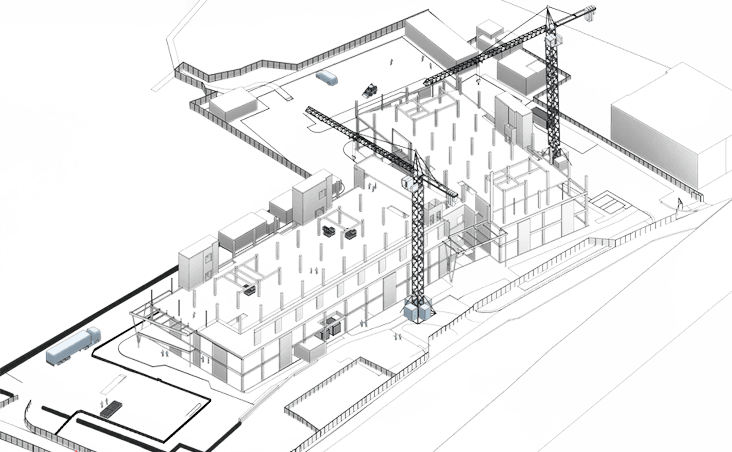

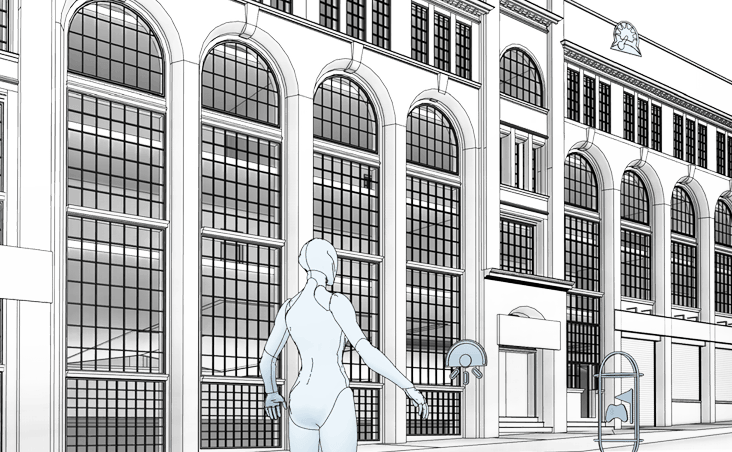

We typically deliver digital twins using a BIM or Scan-to-BIM foundation, anchored by a detailed 3D model of the building. This is enhanced with IoT sensors, installed on-site and connected via secure cloud platforms. Once real-time data flows between the physical asset and its digital replica, it unlocks powerful capabilities.

01

We begin by thoroughly reviewing the project brief, as a digital twin must be clearly defined and refined before development. We work closely with our clients to anticipate challenges, align objectives, and procure the right software and hardware to make the project viable and future-ready.

02

Next, we audit and optimise the digital model. Since many BIM models created for construction aren’t directly usable for operations, we perform a full geometric and data review. We also model and place the proposed IoT hardware within the digital twin to prepare for integration and live data linkage.

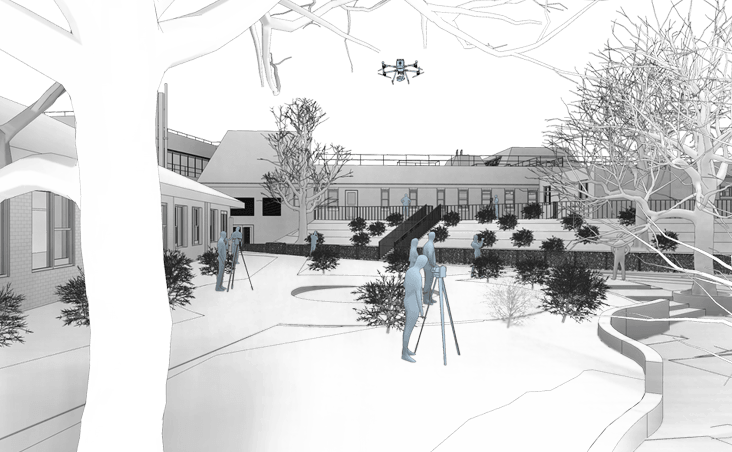

03

Our consultants visit the site to carry out the installation of IoT sensors. This phase is efficient typically taking less than a minute per sensor and ensures all hardware is correctly configured to begin data transmission securely.

04

With the hardware live, automated data collection begins. We then perform data analysis and create custom dashboards tailored to your needs, giving you real-time insights and the ability to monitor and control on-site equipment remotely, directly from the digital twin interface.

Benefits

Live Operational Insights and Monitoring

Digital twins combine real-time sensor data with BIM to monitor energy use, occupancy, air quality and system performance for smarter building management.

Predictive Maintenance and Asset Optimisation

Digital twins simulate building performance to predict failures, optimise maintenance and extend asset life, cutting downtime and lifecycle costs.

Enhanced Planning and Scenario Testing

Digital twins allow stakeholders to simulate "what-if" scenarios such as layout changes, retrofits, or fire evacuations, supporting data-driven decisions without disrupting operations.